Installing a conveyor system at your organization can be a great way to speed things up. There are different types of conveyors and these conveyor systems are used in many different types of businesses all the time. These businesses include mining and manufacturing, warehouse and food, and agricultural just to name a few. Meanwhile, there are a lot of different types of conveyor systems out there, which allows for a lot of adaptability and flexibility in the industry.

Now, the big question you might want to ask yourself would be: Which conveyor system do I need and where can I buy a conveyor system? At CaTS, we have various types of conveyor systems to fit different industries that can aid your work and boost productivity:

What is a conveyor belt system? Conveyor belt systems, which are one of the most common types of conveyors, have found their place in almost every industry. In this system, there are two or more pulleys (or more) and a conveyor belt (the closed-loop) that moves around them. When one or more of the pulleys in the system are run by electricity, they can move the belt in the right direction.

The belt conveyors consist of two types:

With a variety of materials and applications, belt systems may be found throughout a range of industries and industries. Many places, from airports to restaurants to ski resorts, have them transporting people with their equipment and their meals (particularly at sushi restaurants). In order to prevent contamination and material loss, a belt conveyor can be enclosed, but it can also be open when it is part of an assembly line. There is no better option for hauling heavy cargo than these.

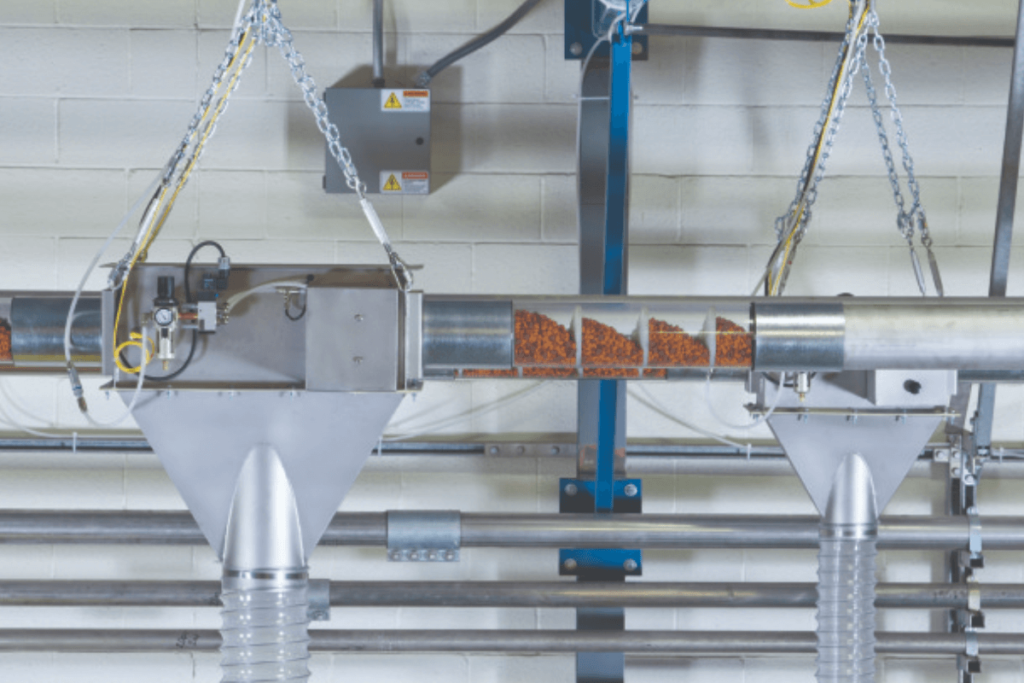

Cable conveyor systems, particularly tubular cable conveyors, are ideal for preserving material integrity and minimizing direct contact with food materials. These systems use a flexible, coated stainless steel drag cable to move material through a sealed tube. The material is pushed through the line by solid discs attached to the cable.

You can use cable conveyors to move material in any direction you want. They can move it vertical, horizontal, at an angle, or around a corner. In order to save money on electricity, they use motors that have 7.5 HP or less. These systems are also easy to keep up with because they have parts that can be taken apart. The cable conveyor systems can be used for moving:

These conveyor systems are ideal for:

Chain conveyors use a long chain to move material down a production line. There are sprockets at both ends of the line, and the chain runs over them. It can also be attached to other things. Chain conveyors are usually used to move heavy loads, like industrial containers, grid boxes, and pallets. They are also used to move things that are very wide or long, like pallets and industrial containers. People in the pharmaceutical and car industries also use this kind of technology. Chain systems are used to move parts of cars through paint plants, making it easier to apply paint.

Overhead conveyor systems are either suspended from the ceiling or attached to a steel structure that is put on the floor. Most of the time, they have more features and can be a little more expensive than the other ones. They do cut down on operating costs, though, because they don’t need a lot of people. The overhead conveyor systems are also known for being very safe, and one reason is that they don’t get in the way of the aisles

Stay up-to-date with all our latest blog posts by subscribing to our notifications.