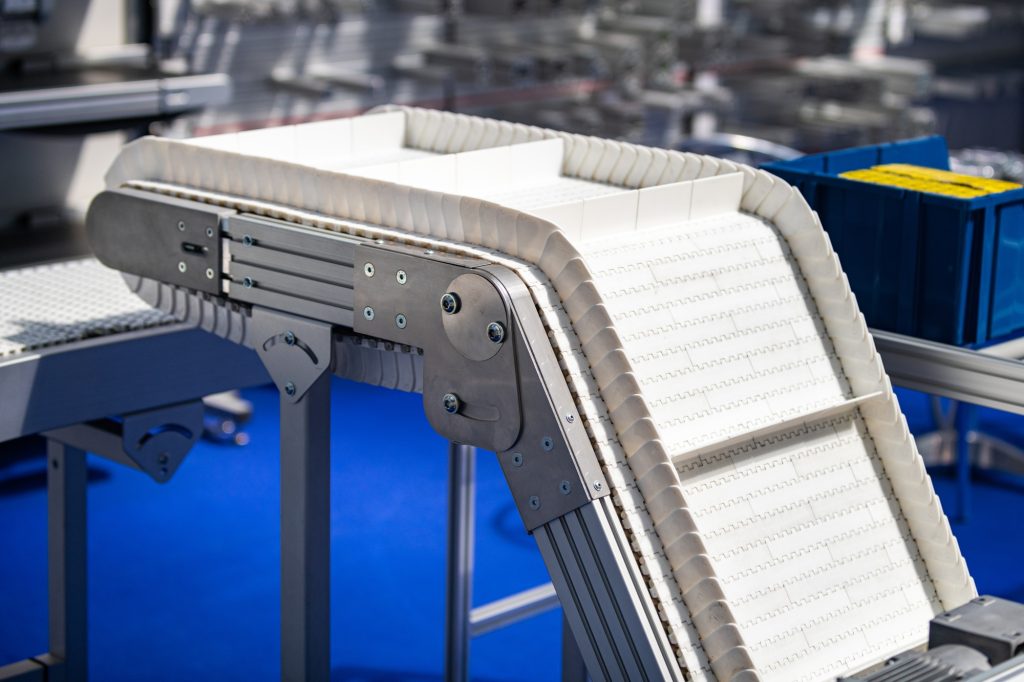

Conveyor belts are integral to efficient industrial operations, providing a reliable way to move materials across production lines and workstations. When functioning optimally, they help maintain productivity and keep workflows smooth. However, like all mechanical systems, conveyor belts are prone to wear and damage, especially in demanding environments. Neglecting early signs of damage can lead to costly breakdowns, prolonged downtime, and decreased operational efficiency.

This guide explores the most frequent types of conveyor belt damage, including their root causes, warning signs, and how to address them effectively. Whether you’re a maintenance planner, plant manager, or production supervisor, understanding these common issues will help you extend the life of your belts, avoid unplanned outages, and maintain a safer work environment.

Overview of Common Conveyor Belt Issues

Conveyor belt problems often start small and escalate quickly when left unchecked. From minor surface abrasions to major structural failures, damages vary in form and severity. Understanding the different types of belt damage is the first step in developing a proactive maintenance plan.

Common issues include frayed edges, torn sections, surface gouges, misalignment, slippage, and abnormal belt tracking. These issues may not be immediately visible, but they often present symptoms such as increased noise, material spillage, and inconsistent belt motion. Regular inspections and knowledge of these signs help minimize disruption and improve system reliability.

13 most common conveyor belt damages, how to identify them, and effective strategies to prevent them

1. Belt Mistracking: Belt mistracking occurs when the belt veers off-center during operation. This is often caused by misaligned pulleys or material build-up along the belt path. To prevent this, it’s important to conduct regular alignment checks and maintain proper belt tension. If mistracking is detected, adjust the tracking rollers and thoroughly clean the pulleys to restore proper alignment.

2. Slippage: Slippage happens when the conveyor belt slips over the pulleys, especially under load. This is typically caused by a worn drive pulley or insufficient belt tension. Preventative maintenance includes monitoring belt tension and inspecting the condition of pulley lagging.

3. Carryback: Carryback is when material sticks to the belt and falls off along the return path. It usually results from inadequate belt cleaning systems. Installing effective scrapers and cleaners can prevent this issue. For existing carryback problems, clean the belt thoroughly and consider upgrading the scraper system for better material removal.

4. Belt Cuts and Gouges: Cuts or deep gouges on the belt surface are common when sharp materials or foreign objects are present. Prevention involves inspecting transported materials and using belt protection devices. Minor damage can be repaired with patch kits, while severe cuts may require vulcanizing the affected area.

5. Surface Wear: Surface wear shows up as thinning or bald patches on the conveyor belt. This is caused by constant abrasion or excessive loads. To prevent surface wear, use wear-resistant belt materials designed for heavy-duty applications.

6. Edge Damage: Edge damage is seen as frayed or torn sides of the belt and is typically caused by misalignment or improper loading practices. Preventive measures include using correct loading techniques and installing guide rollers.

7. Delamination: Delamination occurs when the belt layers begin to separate, often due to moisture intrusion or exposure to harsh chemicals. Choosing belts with sealed edges or chemical-resistant materials can help prevent delamination. When this damage occurs, the affected belt section should be removed and replaced.

8. Splice Failures: Splice failures happen when the belt breaks at the joint, commonly due to poor splicing or overloading. Proper team training on splicing techniques is essential for prevention. If a splice fails, re-splicing with the correct adhesives or mechanical fasteners is recommended for a secure fix.

9. Pulley Lagging Damage: Damage to pulley lagging appears as worn or detached covers on drive or tail pulleys. This issue is typically caused by belt slippage or excessive tension. Regular inspections of pulley lagging are key to preventing this. If damage is found, the lagging should be replaced and pulley alignment checked.

10. Belt Stretching: Belt stretching becomes noticeable when the belt appears longer than usual or sags during operation. This is caused by overloading or prolonged tension. To prevent this, select belts with the appropriate tensile strength for your application.

11. Joint or Fastener Loosening: Loosening of joints or mechanical fasteners is evident when there are visible gaps or missing hardware. This usually occurs due to vibration or improper installation. Prevent it by conducting routine inspections and tightening fasteners to the correct torque specifications. Reinstall or replace any loose or missing fasteners to ensure secure belt operation.

12. Material Spillage: Material spillage happens when materials fall off the sides of the conveyor belt. This typically results from improper loading practices or misaligned skirting. To prevent spillage, use proper loading chutes and ensure skirting seals are maintained.

13. Conveyor Belt Fire Damage: Fire damage presents as burnt or charred belt sections and is caused by overheated motors, friction, or electrical sparks. Prevent this hazard by using fire-resistant conveyor belts and installing appropriate fire suppression systems. In the event of fire damage, immediately replace the affected section and investigate the root cause to avoid future incidents.

Causes of Conveyor Belt Damage

Conveyor belt failures rarely stem from a single event. Instead, they typically result from a combination of mechanical, operational, and environmental factors. The most frequent causes include:

Misalignment: When belts are not properly aligned, they rub against frames or pulleys, causing edge damage.

Overloading: Carrying loads beyond capacity places excessive stress on the belt and supporting components.

Improper material handling: Sharp or oversized objects can puncture or tear the belt surface.

Inadequate tensioning: Incorrect tension can lead to slippage, uneven wear, or accelerated degradation.

Foreign object intrusion: Debris or tools left on the belt path can cause physical damage or block movement.

Incorrect splicing methods: Faulty splicing compromises belt integrity and can lead to sudden failure.

Environmental factors: Exposure to extreme heat, cold, moisture, or corrosive substances can deteriorate the belt material over time.

Understanding these causes allows maintenance teams to design targeted inspection protocols and take preventive action.

When to Replace a Conveyor Belt

Even with regular maintenance and repairs, conveyor belts have a limited service life. Recognizing when it’s time for a full replacement can prevent costly and dangerous breakdowns. Consider replacing your belt if:

It has sustained multiple severe damages across large areas.

Repairs are frequent and no longer cost-effective.

The belt can no longer track properly despite alignment adjustments.

The belt surface is excessively worn, compromising grip and safety.

There are recurring splice failures or material retention issues.

Not sure whether to repair or replace? Book a free consultation with our conveyor belt specialists to evaluate your system’s condition.

Conclusion: Best Practices for Conveyor Belt Maintenance

Proactive conveyor belt maintenance is more than a cost-saving measure—it’s a business continuity strategy. By identifying common damages early, understanding their causes, and applying the right preventive and repair strategies, you can keep your operation running without costly interruptions.

To ensure peak performance:

Conduct regular inspections.

Monitor for unusual wear or behavior.

Repair small damages immediately.

Know when it’s time for a replacement.

Train your team and document every step.

Schedule your free maintenance consultation today and ensure long-term reliability.